What is the CNC milling part? What are the steps of CNC milling?

- Release Time:13 / 03 / 2024

- Author: JOBR

The pursuit of high accuracy and quality finishing in the manufacturing sector has skyrocketed the growth of CNC milling. If we talk in numbers, the global CNC machining industry currently stands at a whopping $100 billion with bright forecasts. Estimates suggest that the industry will reach almost $150 billion by 2032. The widespread adoption of CNC milling by manufacturers reflects its critical importance as it has revolutionized production standards for efficiency, accuracy, and reliability.

What are CNC Milling Parts, and How Does CNC Milling Work?

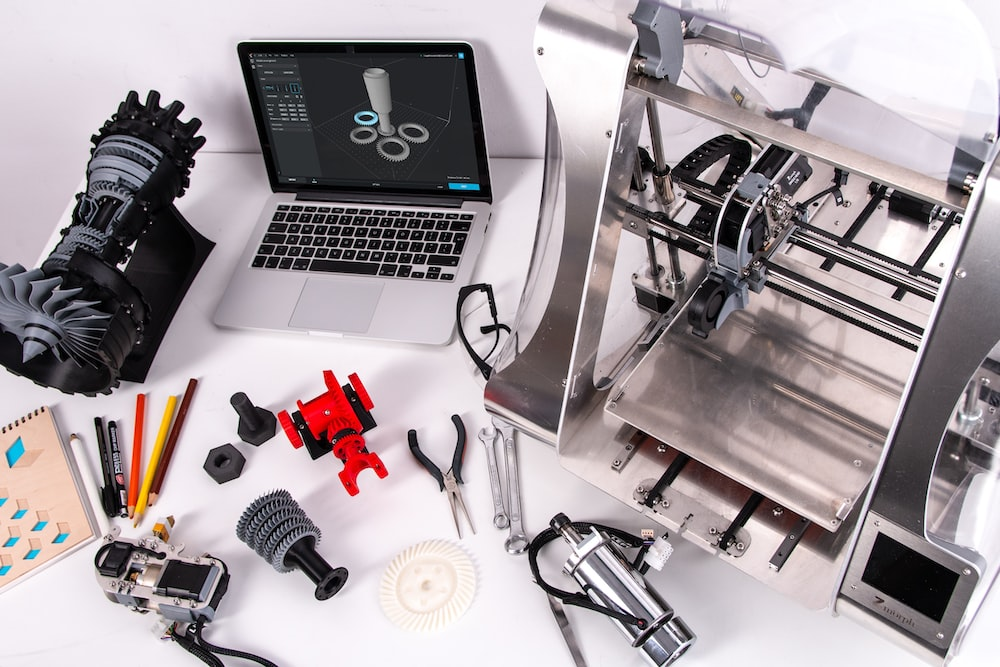

CNC milling parts are the products of a systematic process that starts with a digital blueprint and ends with an exceptionally crafted physical component. These parts are used in various applications in our daily life.

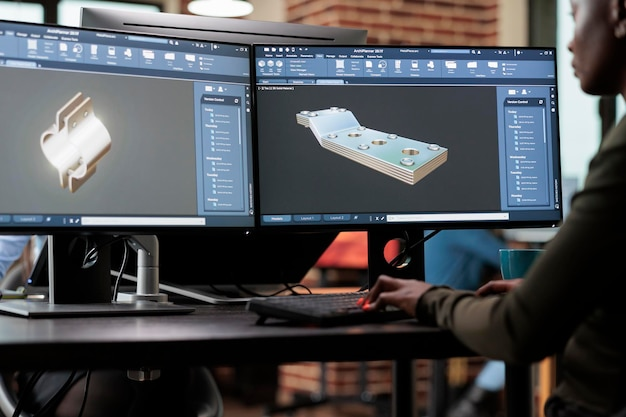

The CNC milling process starts with creating a detailed Computer-Aided Design (CAD) model, which is then converted into a CNC program. Once the machine is precisely set up with the raw material and the appropriate tools, the CNC program guides the cutting tools to convert the raw material into the final design of the prototype.

Applications of CNC milling parts

CNC milling parts are renowned for their precision and versatility, which makes them crucial to a wide array of applications.

In the aerospace sector, CNC milling parts are critical for crafting components that adhere to the most stringent standards for weight, durability, and tolerance. Aircraft engines, landing gear, and cockpit instruments all rely on the high precision of CNC milling.

The automotive industry also benefits significantly from CNC milling. You will see this process in action in the manufacturing of engine components, transmission systems, and custom fixtures.

In healthcare, CNC milling plays a pivotal role in manufacturing surgical instruments, orthopedic implants, and medical devices. Similarly, consumer electronics also leverage the precision of CNC milling parts in the creation of complex components found in smartphones, laptops, and other gadgets. Moreover, CNC milling parts can also be seen in the energy sector in the form of components for wind turbines and other renewable energy equipment.

JOBR CNC machining Recommendation

JOBR stands out for its high-quality CNC milling parts. They offer a broad spectrum of CNC rapid prototyping, including CNC turning, milling, engineering, surface grinding, wire erosion, and EDM spark erosion.

Here's why you should consider JOBR for your CNC machining service:

Material and Finish Variety

JOBR provides machining for an extensive range of materials, including mild and stainless steel, aluminium, magnesium, zinc, brass, and various plastics, not to mention that you get a diverse range of finishing options. Examples of finishing include:

l Bead blasting for a matte appearance.

l Anodizing for corrosion resistance and aesthetic appeal.

l Powder coating for a durable and visually appealing finish.

Precision and Quality

JOBR is committed to delivering high-quality and precise components. We excel in rapid prototyping, ranging from a single prototype to up to 500 parts. With a focus on speed and precision, JOBR's advanced prototyping technology accelerates product development and market entry.

Quality Assurance and Cost-Effectiveness

JOBR's rigorous quality assurance procedures guarantee that your parts exceed expectations. This CNC parts machining is competitively priced, offering significant cost savings compared to US and EU counterparts, and even supports free samples.

FAQS About CNC Milling

Here are some FAQs you may have about CNC milling:

What are the steps of CNC milling?

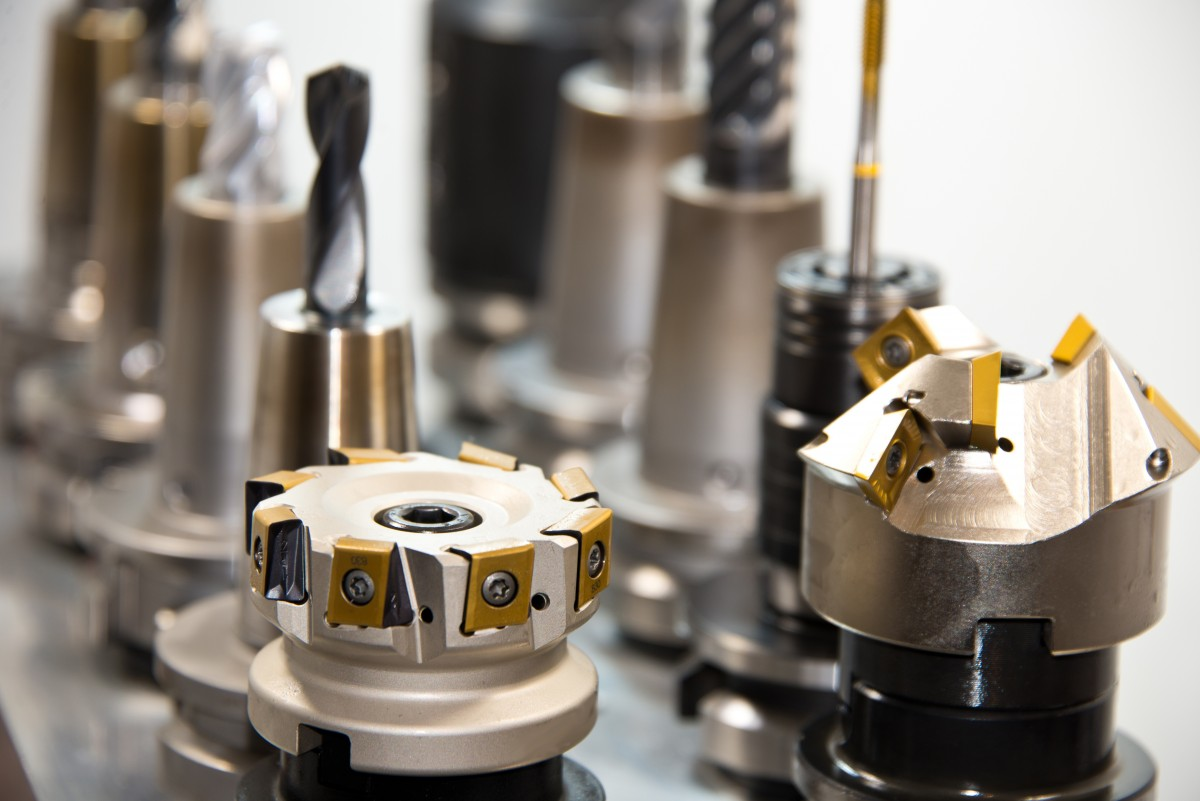

The first step in the CNC milling process is to get a digital design of the part you want to produce. After that, this design is converted into a CNC program through CAM software, which effectively translates the 3D model into precise G-code commands for the CNC machine. Now is the time to make the machine ready for milling. In this phase, the milling machine undergoes a thorough setup involving the selection and installation of appropriate cutting tools, securing the raw material onto the machine bed, and proper calibration to bring accuracy. Once this is done, the CNC machine starts the milling process by converting the raw material into the desired form. After the milling is complete, the newly formed part undergoes a rigorous inspection to ensure the defined quality standards.

What are examples of CNC machined parts?

Some examples of CNC milling parts include aerospace components like:

l Turbine blades and landing gear

l Automotive industry parts such as engine blocks and transmission systems

l Medical devices like orthopedic implants

l Detailed surgical instruments

l Others

What is the Anatomy of CNC Machines?

A CNC has the following key components:

● A frame for structural support for the entire machine.

● Spindles to hold and rotate the cutting tools and are responsible for their rotation.

● Three to five axes (X, Y, Z, and possibly A and B) to allow the movement of the cutting tool and workpiece in various directions.

● A table to hold the workpiece in place during the milling process.

● Tool Changer to switch between different cutting tools without manual intervention, increasing efficiency and reducing downtime.

● A control panel to input the CNC program, monitor the milling process, and make adjustments as necessary.

● Coolant System to dissipate heat generated during the milling process.

What is CNC milling material?

Different CNC milling materials include stainless steel, aluminium, titanium, copper, brass, alloy steel, carbon steel, and plastics.

Wrapping-Up

The remarkable growth and versatility of CNC milling in various industries speak volumes about its role in modern manufacturing. With our commitment to precision, quality, and finishing options, we at JOBR stand as the best choice for your CNC machining needs.