If you have any special designs and material requirements, we can utilize 3D rapid prototyping technology to satisfy your product development needs. 3D prints run through a direct digital manufacturing process, with minimal setups or post-processing.

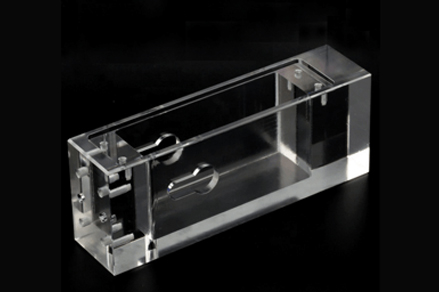

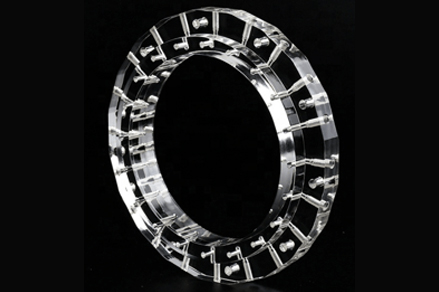

Our advanced technology includes SLA(Stereolithography ) and SLS (selective laser sintering), which are ideal for making rapid, one-off prototypes.

The 3D printing rapid prototype service we offer:

● SLA technology applies UV light to precisely cure a liquid photopolymer into a solid plastic prototype, layer by layer, perfect for rapid prototypes with high-level accuracy.

● SLS technology uses a high-powered laser to fuse powdered nylon, one layer at a time to form a 3D solid without worries about strength and durability.