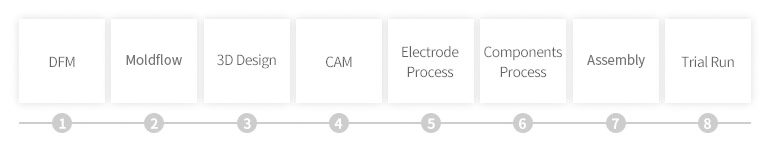

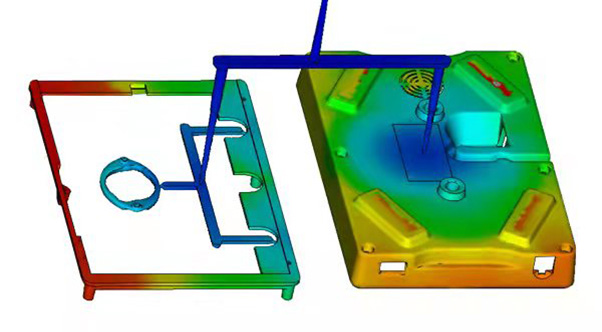

Mold Flow Analysis Design for Manufacture is a helpful tool we can provide to our customers to help minimize tooling costs and expedite the manufacturing process. We will provide a detailed report containing important information about your part design and highlighting any potential problem areas. In addressing design issues early on, the DFM helps to eliminate costly re-tooling or delays in the manufacturing process caused by a problematic part design.

We also can provide mold flow analysis, which can save you money and ensure production in a timely manner when combined with the DFM.