Rapid prototype tooling finished in 5- 28 days.

Rapid aluminum tooling volumes up to 5000+ shots.

P20 prototype tooling volumes up to 20,000+ shots.

NAK80 or S136 prototype tooling volumes up to 100,000+ shots.

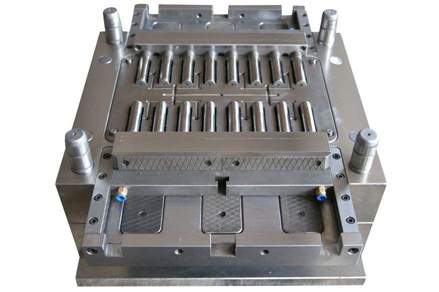

JOBR rapid prototype tooling service can help you manufacture injection mold tools and finished parts in a quick turn. From low-volume injection molding to mass production, rapid tooling can reduce production time and cost.

Whether you want 100 pcs or 1000 pcs parts, or start mass production, quote us now! We will get back to you in 24 hours.

Rapid prototype tooling finished in 5- 28 days.

Rapid aluminum tooling volumes up to 5000+ shots.

P20 prototype tooling volumes up to 20,000+ shots.

NAK80 or S136 prototype tooling volumes up to 100,000+ shots.

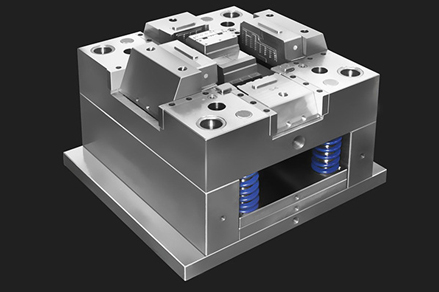

Rapid prototype tooling is an excellent way to simplify the mold structure for low cost & short lead time. It’s commonly used in the rapid injection molding industry, meeting the low-volume requirement.

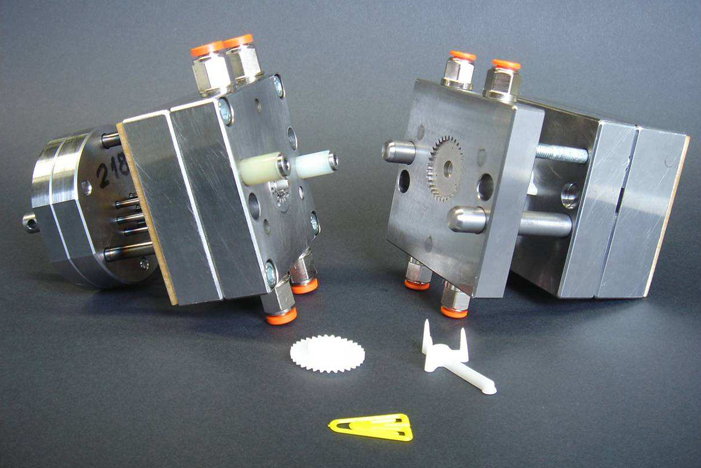

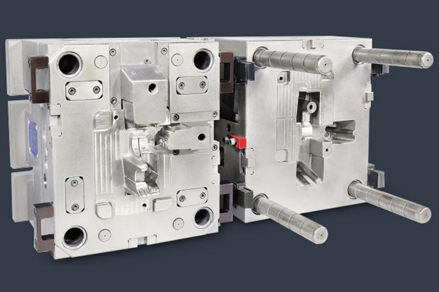

JOBR rapid prototyping and tooling service utilizes 7075 aluminium (molds can be textured) and pre-hardened P20 tool steel to make the cavity, core and ejector plates. Most of our custom injection molding tools use P20 steel, which is more durable and affordable. JOBR steel rapid tool injection molding services deliver more than double the parts of comparable aluminium.

Prototypes produced in production material in shorter timeframes.

Allows for full fit and function testing.

Discovery of any design flaws early on, low cost tooling allows for easy geometry modification and refinement of design.

Material Science:Acetal polyoxymethylene (POM), Nylon 66 (PA66), High-density polyethylene (HDPE), Polybutylene terephthalate (PBT), Glass-filled polycarbonate (PC-GF), Polyethylene terephthalate (PET), Polyphenylene sulfide (PPS), Polystyrene (PS), Thermoplastic elastomer (TPE), Acrylonitrile butadiene styrene (ABS), Glass-filled, polyamide (PA-GF), Low-density polyethylene (LDPE), Polycarbonate (PC), ABS polycarbonate (PC-ABS), Polymethyl methacrylate (acrylic) (PMMA), Polypropylene (PP), Thermoplastic vulcanizates (TPV)

We Process for JOBR Tech's Rapid Prototype Service:

Submit a Request for Quotation (RFQ), enable us to meet your rapid prototype tooling requirements.

Our team will conduct a Design for Manufacturability (DFM) analysis and provide mold drawings for your approval. This ensures that the design is optimized for efficient production.

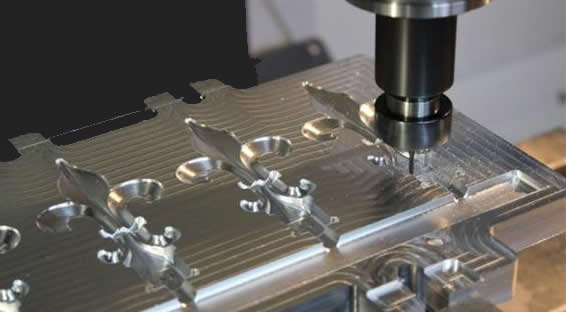

After you have reviewed and confirmed the final mold drawings, our skilled technicians will apply advanced rapid prototyping and tooling technologies to fabricate the molds.

Once the quality inspection is passed, we arrange assembly and packaging for shipment, ensuring that your parts are delivered safely and securely.

At every stage of the process, we maintain strict quality control measures to ensure that your parts are manufactured to the highest standards. As a responsible provider, we take full ownership of the quality assurance process and ensure that the final products meet or exceed your expectations.

We can mass produce custom parts quickly and efficiently. Our mold and production technology allows us to use a

variety of materials and finishes to meet the needs of any industry or application.

Here are some of the options you can choose from:

● China’s excellent end-to-end rapid tooling service: At JOBR, we combine our experience, engineering capabilities, and advanced rapid production tooling technology to support your specific requirements.

● Our experienced engineering team helps you step by step to make the perfect rapid prototyping tools, ranging from part development, mold design, injection molding, assembly and packaging to delivery.

● Wide range of engineering materials to choose from, such as POM, PET, PBT, and TPE for injection molding.

● 24-hour production, effectively prototyping & tooling in short production runs.

● Our advanced rapid prototype tooling technology speeds up your product into the market.

● At every stage of the rapid production tooling, we maintain strict quality control measures to ensure that your molds are manufactured to the highest standards.

● Over 50% cheaper than US/EU prices; Support free samples.

Rapid tooling refers to the quick and cost-effective production of molds or tooling used for low volume injection molding or rapid prototype tooling. It enables the efficient manufacturing of prototypes or small batch production parts using advanced techniques and materials.

Service Process: First, we receive the customer's RFQ (Request for Quotation). Based on the RFQ, we provide a quotation. After the customer confirms the quotation, we proceed with DFM (Design for Manufacturability), mold flow analysis, and mold design. Once the customer approves the mold drawings, we begin the mold manufacturing process. After the mold is completed, we conduct trial molding and perform quality inspections. Finally, we assemble, package, and ship the rapid prototyping tools.

Advantages of our service: Fast delivery, quality assurance, and customization of small-batch production.

We have a management team composed of professional technical experts. With advanced rapid prototype tooling technology, we provide end-to-end services ranging from part development, mold design, injection molding, assembly and packaging, to delivery. We have extensive experience in custom production using engineering materials such as PEEK, PPSU, PBT, LCP, and PBT for injection molding.

Rapid tooling offers several advantages in product development, including:

Faster time-to-market: Rapid tooling allows for quicker production of molds or tooling, reducing overall product development time.

Cost-effective production: With rapid tooling for injection molding, small batch production can be done efficiently, minimizing costs.

Design validation: Rapid tooling enables the creation of physical prototypes for design verification and functional testing, ensuring product performance and quality.

JOBR Tech utilizes a variety of materials for rapid tooling, including aluminum tooling. Aluminum offers advantages such as excellent thermal conductivity, lightweight properties, and cost-effectiveness, making it suitable for rapid tooling applications.

The lead time for rapid tooling projects varies depending on factors such as design complexity and production requirements. At JOBR Tech, we prioritize fast turnaround times and work closely with clients to meet their specific project timelines.