Plastic: ABS, PC, POM, PMMA (Acrylic), Learn More about our Plastic Machining

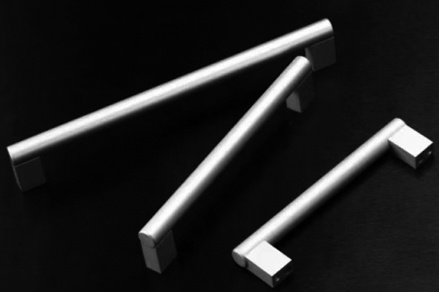

Metal: Aluminum, Steel, Stainless Steel, Magnesium, Titanium, Zinc, Brass, Bronze, Copper. Learn More about our Metal Machining.

CNC machining is a kind of manufacturing process to make full use of computer-controlled machine tools, producing more precise plastic and metal parts from one single prototype to up to 500 parts. Our CNC rapid prototyping supports a wide variety of materials, including mild and stainless steel, aluminum, magnesium, zinc, brass, and many plastics.

Our CNC machining prototype service includes CNC turning, CNC milling, CNC engineering, surface grinding, wire erosion, and EDM spark erosion.

We will offer you high-quality and precise components in the short term, and provide original certificates for all materials used in the parts. All of your parts design will be discussed carefully and checked before production starts. After production, your parts will be 100% inspected to meet the industrial standards.

Plastic: ABS, PC, POM, PMMA (Acrylic), Learn More about our Plastic Machining

Metal: Aluminum, Steel, Stainless Steel, Magnesium, Titanium, Zinc, Brass, Bronze, Copper. Learn More about our Metal Machining.

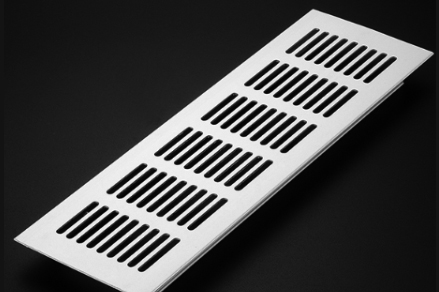

Bead Blasted: The part is left with a matt appearance. A range of 120 to 320 beads allows us to create different roughness on the surface.

Anodized:

Type II creates a corrosion-resistant finish. Parts can be anodized in different colors—clear, black, and red. Blue is the most common—usually associated with low silicone element series of aluminum.

Type III is thicker and creates a wear-resistant layer, in addition to the corrosion resistance with Type II.

Powder Coat: This is a process where powdered paint is sprayed onto a part, and then baked in an oven. This creates a stronger and durable layer than standard painting methods, with a variety of colors available to create different styles.

We Process for JOBR Tech's Rapid Prototype Service:

Submit your RFQ (Request for Quotation) to us, including specific requirements for CNC machining, CNC milling parts and CNC rapid prototyping.

Our team conducts Design for Manufacturability (DFM) analysis and provides mold drawings for your approval. This ensures that the design is optimized for efficient CNC machining processes.

Upon your confirmation of the final mold drawings, with state-of-the-art CNC machines, our experienced technicians meticulously execute the machining processes to create the precise parts.

Thorough quality check, we will deliver your CNC machining product in a short time.

At JOBR Tech, we take full responsibility for ensuring that your parts are manufactured to our high-quality standards. Our rigorous quality assurance procedures and inspections throughout the CNC machining process guarantee that your parts meet or exceed your expectations.

We can mass produce custom parts quickly and efficiently. Our mold and production technology allows us to use a

variety of materials and finishes to meet the needs of any industry or application.

● China’s excellent CNC machining services: At JOBR, we combine our experience, engineering capabilities, and advanced CNC machine tools to support your specific requirements.

● Our experienced engineering team helps you step by step to make the perfect parts, from initial design to final delivery.

● Wide range of plastic materials & colors to choose

● 24-hours production, effectively CNC machine prototyping in short production runs.

● Our advanced prototyping technology speeds up your product into the market.

● At every stage of the precision-machined product, we maintain strict quality control measures to ensure that your molds are manufactured to the highest standards.

● Over 50% cheaper than US/EU prices; Support free samples.

CNC rapid prototyping is a process that utilizes Computer Numerical Control (CNC) machining techniques to quickly fabricate high-precision prototypes and functional parts. It combines the speed and accuracy of CNC machining with the flexibility of rapid prototyping to accelerate product development.

Service Process: First, we receive the customer's RFQ (Request for Quotation). Based on the RFQ, we provide a quotation. After the customer confirms the quotation, we proceed with DFM (Design for Manufacturability), mold flow analysis, and mold design. Once the customer approves the mold drawings, we begin the mold manufacturing process. After the mold is completed, we conduct trial molding and perform quality inspections. Finally, we assemble, package, and ship the products.

Advantages of our service: Fast delivery, quality assurance, and customization of small batch production.

We have a management team composed of professional technical experts. With advanced mold technology and strong manufacturing engineering capabilities, we provide end-to-end services ranging from part development, mold design, injection molding, assembly, packaging, to delivery. We have extensive experience in custom production using engineering materials such as PEEK, PPSU, PBT, LCP, and PBT for injection molding.

CNC rapid prototyping offers several advantages in product development, including:

Faster iteration: With the ability to quickly create prototypes, designers and engineers can iterate and refine their designs more rapidly, reducing development time.

High accuracy and quality: CNC machines provide precise and consistent results, ensuring that the prototyped parts closely match the intended design specifications.

Material variety: CNC rapid prototyping supports a wide range of materials, including metals, plastics, and composites, allowing for versatile prototyping options.

CNC rapid prototyping can be used to produce various types of parts, including complex geometries, intricate components, and functional prototypes. At JOBR Tech, we specialize in CNC milling parts, offering exceptional accuracy and surface finish for your prototyping needs.

Yes, JOBR Tech is experienced in handling custom CNC Rapid Prototyping projects. We work closely with clients to understand their specific requirements and provide tailored solutions. Our team of experts ensures that the prototyped parts meet the desired specifications and quality standards.