CNC Machinery Safety Checklist for Employee and Environment

- Release Time:03 / 11 / 2023

- Author: JOBR

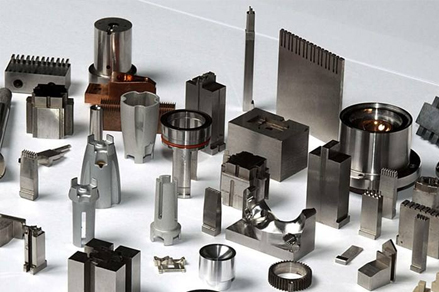

The field of CNC (Computer Numerical Control) manufacturing is currently experiencing a substantial change due to technological progress, which is enhancing the accuracy and effectiveness of production methods. As this industry develops, CNC machining enterprises must embrace increased social accountability, particularly concerning the safety of machinery, the welfare of workers, and the safeguarding of the environment. It is not merely a legal mandate but also a moral duty for these companies to guarantee the well-being of their employees and the ecosystem. This piece will provide a checklist focused on both promoting employee welfare and ecological conservation through machinery safety measures.

CNC Machine Safety Checklist

Here is a CNC machine safety checklist that will make these machines more effective and safer for employees.

Emergency Stop Button

This is a crucial feature that allows the machine to be immediately shut down in case of an emergency. All the operators should be well aware of the use cases of this button to avoid any unfortunate incident.

Soundproof Casing

The soundproof casing of a CNC machine is crucial for machinery safety as it helps to reduce the noise produced by the machine, not to mention that it also protects the operator from flying fragments of tools and other flying objects.

Curtain Guards

Curtain guards are usually made of PVC and are particularly used to save the operator from tool fragments or airborne chips.

Guard Fence

Guard fences improve machinery safety by bringing a physical barrier that separates any workforce from the working area of the machine. This way, operators are always away from the machine's moving parts that threaten their safety.

Contact Mats

These pressure-sensitive mats stop the CNC machine immediately when the operator stands on them, protecting them from moving parts.

Safety Manual

It is essential that every operator is familiar with the CNC machinery safety manual, which contains important information on the machinery safety and maintenance of the machine.

By complying with these critical safety measures of the CNC machining process, CNC machines can be safer and more secure for operators.

Safety Checklist for Environment

Now, let's see how CNC machines can be used for better environmental protection.

Waste management

Managing waste is a crucial environmental aspect related to CNC machining. You need to ensure that you properly dispose of all the waste, such as metal shavings, coolants, lubricants, and packaging, all of which can result in environmental pollution otherwise. One of the crucial strategies to combat waste management is to employ innovative methods like recycling, reusing, or minimizing the waste generated.

Energy consumption

CNC machining also contributes to another important challenge: energy consumption. The machines need a significant amount of electricity to function, which can lead to the emission of greenhouse gasses and climate change, particularly if they operate for long durations. The best way to address this problem is to optimize machine settings for minimum energy usage. This can be done by adjusting different parameters, like feed rate, spindle speed, and cutting depth, to attain optimal performance and efficiency.

Chemical pollution

CNC machining is significantly affected by chemical pollution arising from contact with diverse chemical hazards like coolants, lubricants, solvents, and metal fragments. Failure to manage these chemicals adequately can result in various health issues, encompassing skin irritation, respiratory troubles, allergies, and, in extreme instances, cancer. To mitigate these health hazards, it is recommended that you employ the appropriate coolant and lubricant type and amount for both the machine and the material while also ensuring appropriate disposal practices.

JOBR Cares about Employees and the Environment

JOBR is a company that places a high priority on social responsibility, caring for its employees, and protecting the environment. This commitment is reflected in the following ways:

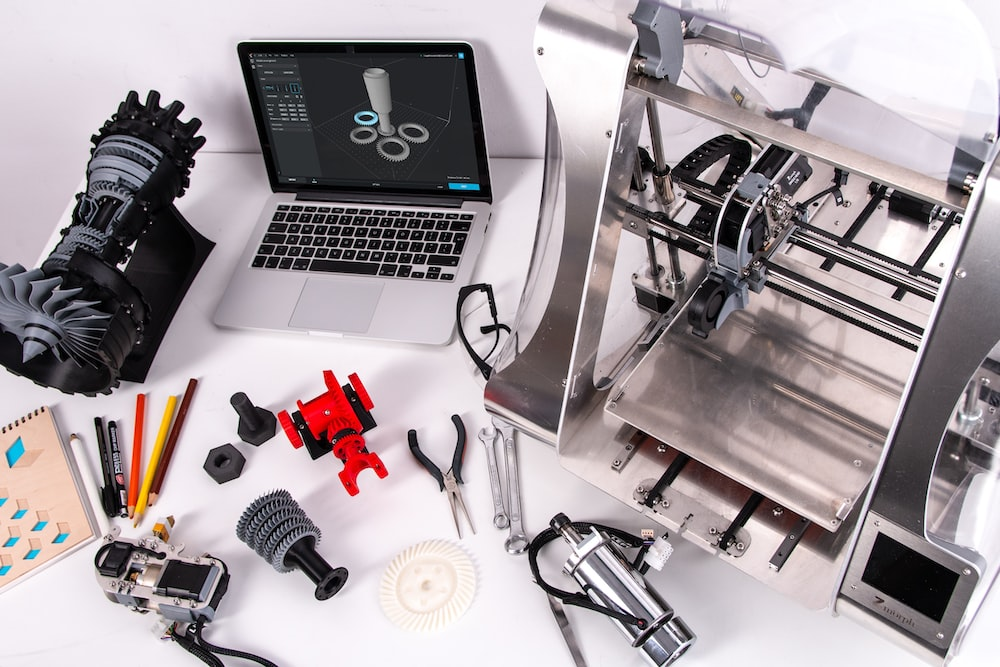

Advanced automatic CNC machines

JOBR has highly advanced automatic CNC machines that are made with the help of cutting-edge technology. They have a well-trained team of professionals who take pride in bringing innovation to CNC machinery safety. With the help of their innovative approaches, they manufacture parts without compromising employees or environmental safety.

Complete quality management system (ISO9001)

At JOBR, quality is not just a priority but the essence of the enterprise. As a leading and responsible CNC machine company, their commitment to achieving the highest possible quality underpins every aspect of their work. This commitment is reflected in the continuous monitoring and control of every process, as well as in the active efforts to reform and improve existing quality standards. This comprehensive approach to quality is also evident in their ISO9001 certification, which ensures that their customers can always be confident in the exceptional quality of their products.

Eco-friendly CNC machining materials

Apart from machinery employee safety, JOBR also focuses on environmental protection in all our activities and is concerned with the environmental impact of our products. JOBR advises customers to choose reasonable materials as per their product requirements so that customers do not breach any environmental regulations for manufacturing CNC parts.

Commitment to regulatory and legal requirements

JOBR adheres to all regulatory and legal obligations, complying with applicable national laws, industry standards, and specifications. The company is dedicated to enhancing its employees' awareness of environmental issues, promoting energy conservation, utilizing resources carefully, preventing pollution, and consistently working towards improving its environmental performance.

Wrapping-Up

As the CNC industry continues to evolve, it is of utmost importance for CNC machining companies to take on greater social responsibility. JOBR stands out as a company that prioritizes social responsibility, employee care, environmental protection, and machinery safety all at the same time. With our advanced automatic CNC machines, complete quality management system (ISO9001), eco-friendly CNC machining materials, and commitment to regulatory and legal requirements, JOBR not only ensures the safety of our employees but also minimizes our environmental impact.

- Prev:No More

- Next:Everything You Need to Know About Rapid Prototype Service