Everything You Need to Know About Rapid Prototype Service

- Release Time:18 / 01 / 2024

- Author: JOBR

Rapid prototyping is a game-changing technology in the product development and manufacturing industries. This technique is widely employed in industries including automotive, aerospace, medical, consumer electronics, architecture, and entertainment. This popularity of rapid prototype service is attributed to its highly streamlined process of creating premium-quality prototypes quickly, which allows designers and engineers to materialize their concepts with unprecedented speed and precision. Using this technique allows you to rapidly create and prototype designs before producing them at scale.

Process Technology of Rapid Prototype

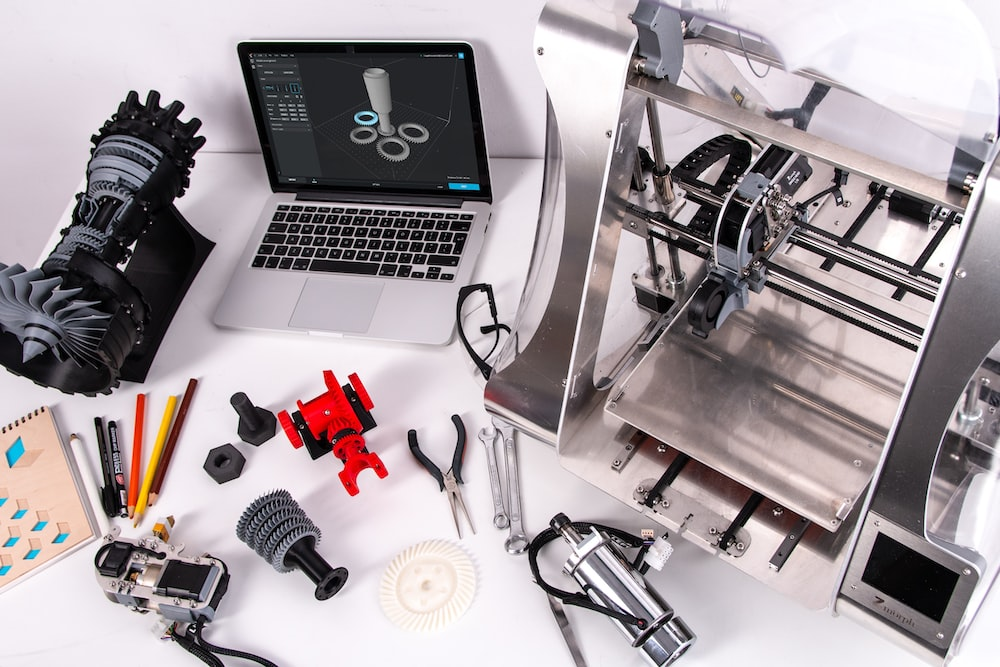

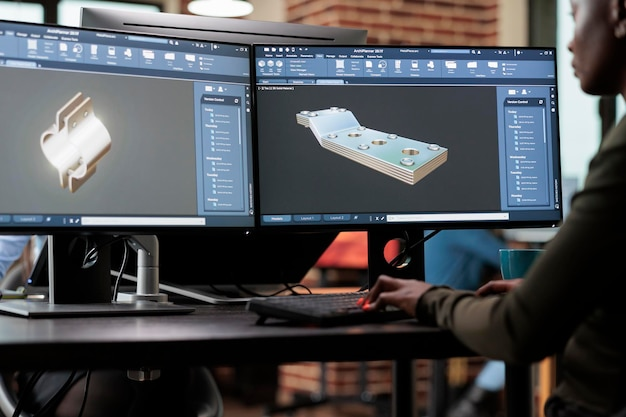

The essence of rapid prototype service lies in its advanced process technologies. Among these advanced technologies, 3D printing, rapid prototyping, and CNC machining prototyping top the list.

l 3D printing, or additive manufacturing, builds objects layer by layer from digital models. It is known for its versatility in handling various materials and its ability to create intricate and complex designs quickly.

l CNC machining is a subtractive process that works by removing (usually by drilling, milling, cutting, etc.) material from a solid block using high-precision tools controlled by computer programming.

Uses of Rapid Prototype

While rapid prototype service has been instrumental in product development in various ways, some of its exceptional advantages include:

Validation in New Product Development

Rapid prototyping creates highly accurate prototypes that are beneficial for designers and engineers who have to test their designs at all stages of production. Not to mention that companies eliminate their production flaws at early stages of development using this technology, which eventually reduces the risk and cost of later-stage modifications.

Creation of Finished Products for Display and Promotion

Rapid prototyping manufactures parts that are often used in marketing, presentations, and trade shows, where showcasing a tangible, high-quality representation of the product makes your product stand out. This approach helps generate interest and feedback from potential customers and stakeholders before the product is available on the market.

Production of Small Batches and Complex Parts

Rapid prototype service is an invaluable asset for directly producing small batches of parts, especially those that are complex or require a high degree of customization. This application mainly benefits specialized industries or products produced in small quantities.

JOBR Rapid Prototype Service

JOBR rapid prototype service is a cutting-edge solution for industries seeking to produce highly sophisticated prototypes before developing the actual product. Specializing in both 3D printing rapid prototyping and CNC machining prototyping, we at JOBR offer a comprehensive approach to translating ideas into tangible products. Choosing JOBR for your rapid prototyping services brings the following benefits to the table.

Professional Team

JOBR has a highly experienced engineering team that guides you throughout the process. Right from the initial product design to the functional testing stage, we bring a seamless and efficient prototyping experience.

One-Stop Services

Their range of services covers everything from 3D printing and CNC machining to surface finishing and quality inspection, providing a complete solution under one roof.

Fast Delivery

With a focus on rapid production, JOBR is capable of meeting tight deadlines and delivering prototypes reliably and efficiently within a few days. This way, you can bring your actual product into the market really quickly.

Quality Assurance

JOBR is committed to high standards of quality as we oversee every manufacturing stage so that the final product meets rigorous quality criteria.

Competitive Price

We offer cost-effective solutions that are significantly more affordable than those of many US/EU counterparts without compromising on quality.

Rapid Prototyping Production Process at JOBR

And JOBR straightforwardly brings all of these advantages. Here is the step-by-step method to get your rapid prototypes ready within days.

Submit RFQ

The process begins with the submission of a Request for Quotation (RFQ), where you will detail your project requirements, timelines, material needs, and part specifications.

Confirm Quotation & Design

JOBR's team conducts a Design for Manufacturing (DFM) analysis to ensure design feasibility, followed by providing detailed mold drawings for your approval.

Confirm Mold Drawing & Production

Once the mold drawings are reviewed and approved, JOBR proceeds with the rapid production process by utilizing advanced prototyping techniques.

Delivery

After the completion of the prototype, it undergoes a thorough quality check. Once verified, the prototype is assembled, packaged, and shipped to you.

Quality Assurance

Throughout the process, JOBR maintains a strict quality control protocol to guarantee that the final product not only meets but exceeds your expectations.

Wrapping-Up

JOBR's rapid prototype service excels in turning innovative designs into high-quality prototypes quickly and efficiently. Our expertise in 3d printing, rapid prototyping, and CNC machining prototyping, combined with a focus on quality and speed, makes us a top choice for businesses needing rapid prototyping solutions.