3D Printing Rapid Prototyping FAQs: What is rapid prototyping in 3D printing?

- Release Time:21 / 02 / 2024

- Author: JOBR

3D printing rapid prototyping is known as one of the most cost-effective ways to make quick prototypes. The process turns highly sophisticated digital designs into prototypes with remarkable speed and in an environmentally friendly manner. 3D printing rapid prototyping represents a massive step forward in the manufacturing sector due to its cost-effectiveness. With this technique, industries can easily get the prototypes of different parts before kicking off bulk production runs.

FAQs about 3D Printing Rapid Prototyping

There needs to be more clarity about 3D printing rapid prototyping. Here are all the answers you need to know.

Is 3D printing good for prototyping?

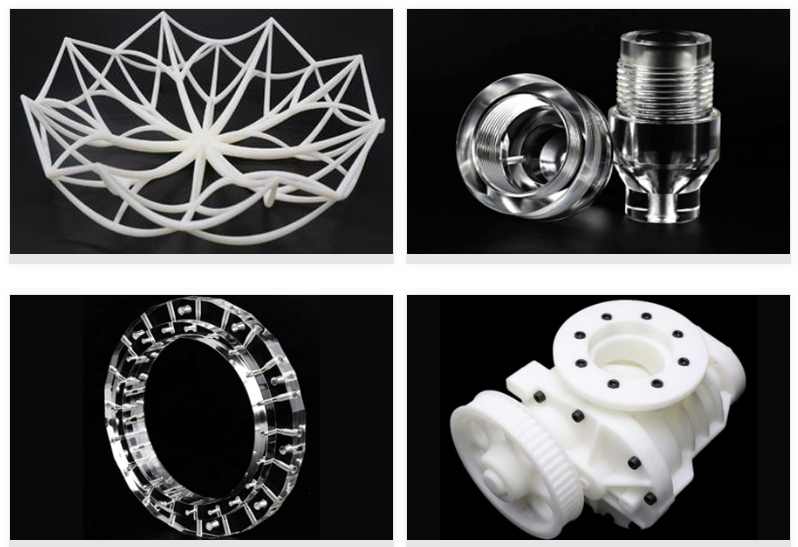

Absolutely. 3D printing rapid prototyping is a well-known prototyping method for many compelling reasons. The most important reason for its popularity is the reduction in time and cost to convert your concept to a physical prototype. Additionally, 3D printing allows iterative design with ease and minimizes environmental waste. Its capability to produce complex geometries at a relatively low price makes it an invaluable asset for prototyping.

Is 3D printing the same as rapid prototyping?

Not exactly. 3D printing is just one method of rapid prototyping. Its types contain techniques like Stereolithography, Selective Laser Sintering, Digital Light Processing, Laminated object manufacturing, and Fused Deposition Modeling. Other than 3D printing, rapid prototyping can be done using CNC Machining.

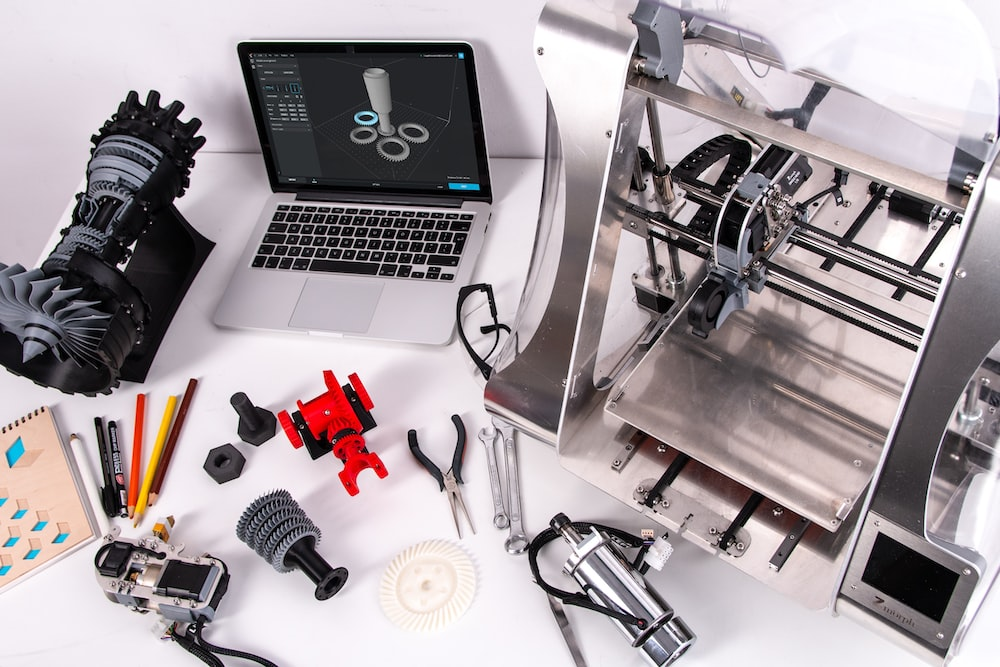

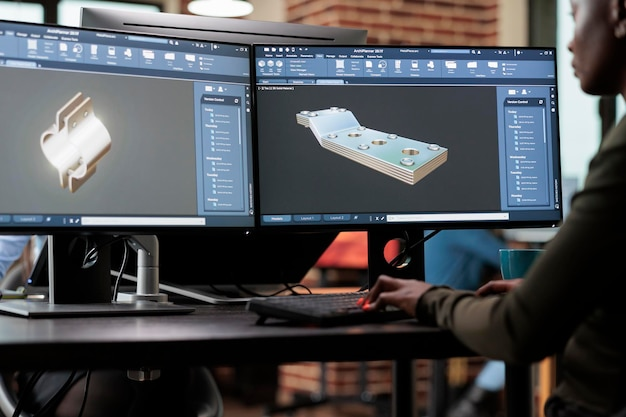

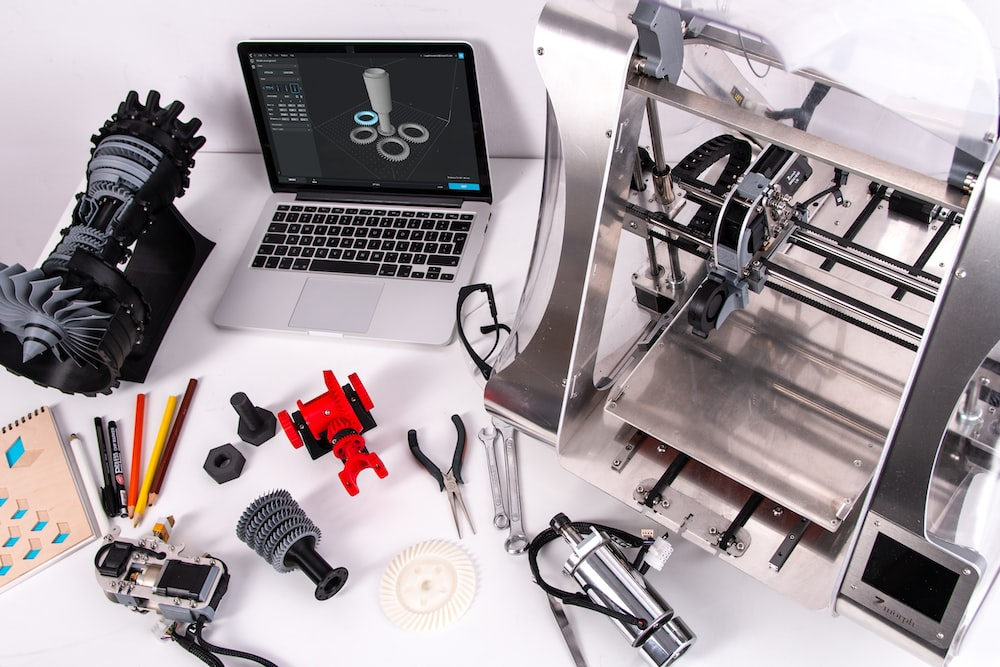

How is 3D printing used to produce a prototype?

The first step is to create a 3D printing model using CAD software, which is then converted to the Standard Tessellation Language (STL) format for printing. The 3D printer is now prepared for printing, including refilling the raw materials, calibrating the platform, and implementing any custom instructions. The 3D printer reads the STL file and starts the printing process. After the printing is complete, the object often requires post-processing. Finally, the printed object is inspected for accuracy, dimensions, and imperfections.

How much does it cost to make a prototype?

There is no single answer to this. You can expect a product anywhere between $30 to thousands of dollars. The actual cost of rapid 3D printing prototyping depends on different factors like the prototype's size, complexity, material choice, and post-processing needs.

Why is 3D printing still not widely used in industries?

There are many misconceptions about 3D printing and rapid prototyping that are hindering its growth in industries. Sometimes, industries face material limitations in 3D printing, which urges them to turn to other methods. Even though it is a quick and effective technique for rapid prototypes, it becomes unsuitable for large-scale production runs. Also, 3D printing is usually less accurate than other techniques like CNC machining.

Look No Further Than JOBR

JOBR's rapid prototyping service is, hands down, the most premium choice for transforming your innovative ideas into physical products.

Let's look at the reasons why JOBR should be your place for 3D printing rapid prototyping.

Comprehensive Service Range

The best thing about JOBR is its extensive range of services for rapid prototyping. We offer advanced manufacturing technologies like 3D printing, rapid prototyping, CNC plastic and metal machining, sheet metal fabrication, plastic injection molding, die casting, silicone mold and vacuum casting, and much more. With this much flexibility in manufacturing, you do not need to look anywhere else for your highly specialized needs.

Quality and Speed Combined

JOBR takes care of quality religiously without compromising on speed. We are equipped to move swiftly from design to mass production, which will significantly cut down your time-to-market by offering fast prototyping.

Advanced 3D Printing Technologies

JOBR's 3D printing rapid prototyping services utilize state-of-the-art technologies like SLA (Stereolithography) and SLS (Selective Laser Sintering). These methods are perfect for creating rapid, one-off prototypes with high accuracy, strength, and durability, with all the customization you need.

Precision CNC Machining

JOBR's CNC rapid prototyping will also cover your highly personalized products with advanced mechanical properties. We work with a diverse range of materials to give your prototype design specifications, desired strength and functionality.

Cost-Effective Solutions

JOBR prides itself on offering services that are over 50% cheaper than US/EU prices. This cost-effectiveness, coupled with our commitment to quality and speed, makes JOBR an attractive option for your rapid prototyping needs.

Wrapping-Up

JOBR's rapid prototype service is a transformative experience for your manufacturing process. With our comprehensive service range, unmatched quality, speed, cutting-edge technologies, and cost-effective solutions, JOBR stands and leaves everyone behind. Make the smart choice and let JOBR be the catalyst for your product's journey from a simple concept to a market leader.