What is Quick Turn Tooling: Advantages, Processes and Materials

- Release Time:26 / 09 / 2023

- Author: JOBR

JOBR Tech, a leading provider of rapid tooling solutions, offers high-quality and cost-effective services over 50% cheaper than US/European counterparts. With a focus on quick turn tooling, JOBR Tech is your trusted partner for efficient and affordable manufacturing. By utilizing various materials and finishing options, we deliver rapid prototype tooling that caters to diverse customer requirements. Explore the benefits, process and materials of quick turn tooling and discover how JOBR Tech can bridge the gap to production seamlessly.

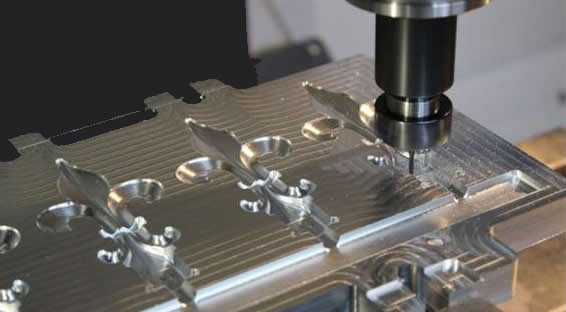

What is Quick Prototype Tooling

At JOBR Tech, quick prototype tooling is the key to simplifying mold structures and achieving low-cost, short lead times. This approach is particularly suitable for fast injection molding projects with low-volume requirements. JOBR Tech manufactures its quick tooling using high-quality materials such as 7075 aluminum (with the option for textured molds) and pre-hardened P20 tool steel. These materials create a cavity, core, and ejector plates, ensuring durability and precision.

Fast and Efficient Production Process

JOBR Tech offers a streamlined bridge to the production process, enabling a quick transition from rapid prototype tooling to high-volume manufacturing. With lead times ranging from 5 to 28 calendar days, we deliver rapid aluminum tooling for volumes of up to 5000+ shots. Additionally, JOBR Tech provides P20 prototype tooling for up to 20,000+ photos and NAK80 or S136 prototype tooling for volumes of up to 100,000+ pictures. This efficient process ensures a smooth progression from prototyping to mass production.

Advantages of Rapid Injection Molding

Rapid injection molding offers numerous advantages for product development and manufacturing:

Production Material Prototypes: With rapid injection molding, prototypes can be produced using the actual production material. This allows for comprehensive fit and function testing, ensuring that design flaws are identified early in the process.

Easy Design Refinement: Low-cost tooling in rapid injection molding facilitates easy geometry modification and refinement of the design. This flexibility enables iterative improvements and enhances the final product's quality.

Materials for Rapid Injection Molding

At JOBR Tech, we have an extensive repertoire of materials available for rapid injection molding. Our capabilities encompass a wide range of options, including Acetal polyoxymethylene (POM), Nylon 66 (PA66), High-density polyethylene (HDPE), Polybutylene terephthalate (PBT), Glass-filled polycarbonate (PC-GF), Polyethylene terephthalate (PET), Polyphenylene sulfide (PPS), Polystyrene (PS), Thermoplastic elastomer (TPE), Acrylonitrile butadiene styrene (ABS), Glass-filled polyamide (PA-GF), Low-density polyethylene (LDPE), Polycarbonate (PC), ABS polycarbonate (PC-ABS), Polymethyl methacrylate (acrylic) (PMMA), Polypropylene (PP), and Thermoplastic vulcanizates (TPV). This diverse range of materials allows us to tailor our rapid injection molding solutions to meet your specific project requirements, ensuring optimal final product performance, durability, and functionality.

Conclusion

JOBR Tech's quick turn tooling services revolutionize manufacturing by offering high-quality and cost-effective solutions. With our expertise in rapid prototype tooling, we bridge the gap between prototyping and production seamlessly. By utilizing advanced materials and efficient processes, JOBR Tech delivers rapid injection molding services that meet diverse customer needs. Experience accelerated production and exceptional value with JOBR Tech's quick turn tooling solutions. Contact JOBR Tech today to unlock the full potential of your manufacturing projects.