Revolutionizing Production with JOBR Tech's Innovative Plastic Injection Molding Services

- Release Time:21 / 09 / 2023

- Author: JOBR

JOBR Tech is proud to welcome you to the world of cutting-edge manufacturing. As the world's potential grows, we're here to introduce you to the cutting edge of innovation: plastic injection molding. This path incorporates the integration of cutting-edge technology and specialist knowledge to provide unparalleled services to businesses of all sizes and in all sectors. The innovative plastic injection molding services offered by JOBR Tech will be explored in detail.

How Plastic Injection Molding Works

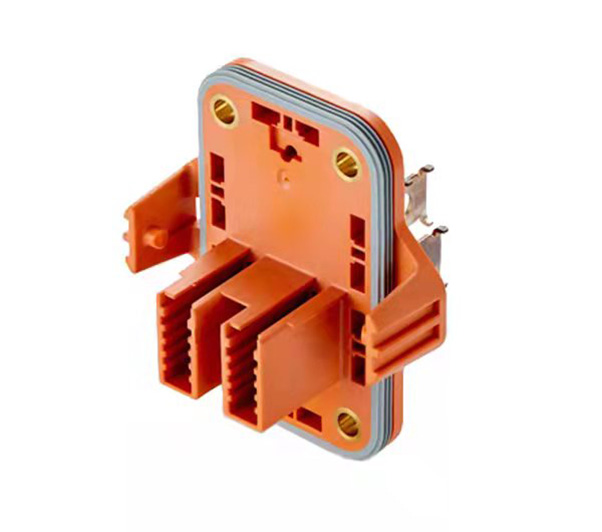

Plastic injection molding is a dynamic manufacturing process that breathes life into a diverse range of plastic components. At JOBR Tech, this technique marries cutting-edge technology with skilled craftsmanship, propelling the creation of intricate parts with unrivaled precision. The process involves injecting molten plastic material into a meticulously crafted mold cavity, allowing it to cool and solidify, resulting in the birth of custom plastic parts.

Variants of Injection Molding: Overmolding and Insert Molding

Diving deeper into the world of plastic injection molding, JOBR Tech offers two distinct variants: overmolding and insert molding. Overmolding pioneers the art of combining materials to craft chemically bonded parts. Insert molding, on the other hand, allows for the integration of plastic coatings onto pre-fabricated substrates, facilitating the creation of multifaceted products. This versatility extends our capabilities, providing tailored solutions to meet specific manufacturing requirements.

Materials that Shape Possibilities

At JOBR Tech, material science takes center stage. Our spectrum of materials reads like an industry anthology: Acetal polyoxymethylene (POM), Nylon 66 (PA66), High-density polyethylene (HDPE), and more. This diversity ensures that every envisioned design finds its ideal embodiment, marrying the form with function seamlessly.

The JOBR Tech Injection Molding Process

The JOBR Tech journey begins with your Request for Quotation (RFQ), serving as the foundation of our partnership. After you have received and confirmed the quotation, our Design for Manufacturability (DFM) analysis commences, optimizing your design for precision molding. Upon your approval, our adept technicians orchestrate the production process, where state-of-the-art equipment and techniques merge to create the molds. Quality checks are a pivotal juncture, ensuring every product adheres to our uncompromising standards before assembly, packaging, and secure delivery.

The JOBR Tech Advantage

Why choose JOBR Tech for your plastic injection molding needs? Established in 2013, we stand as a testament to technological prowess and unwavering commitment. Our dedicated R&D team, fortified by ISO9001 certification, ensures that every facet of our operation exemplifies excellence. Our hallmark lies in our rapid response time, ensuring inquiries are met within 8 hours, and our 24-hour production cycle. Rigorous inspections, a confidentiality system, and an unmatched affordability, with products costing more than 50% less than those in the US/EU, complete the JOBR Tech experience.

In Conclusion: Embracing Possibilities

As we conclude this journey through JOBR Tech's plastic injection molding services, the power of innovation beckons. This transformative technique bridges creativity and technology, reshaping industries and carving new avenues. With plastic injection molding, the future is tangible, intricate, and incredibly efficient. As JOBR Tech continues to shape excellence, we invite you to be part of this extraordinary evolution, where imagination meets precision and possibilities are forged with every custom part.