Plastic Injection Molding: Revolutionizing Manufacturing with Jobr Tech

- Release Time:18 / 08 / 2023

- Author: JOBR

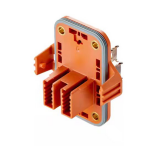

Plastic injection molding is a versatile manufacturing technique that involves injecting molten plastic material into a mold cavity. As a leading provider in this field, Jobr Tech brings advanced manufacturing capabilities, customized solutions, quality assurance, and timely delivery to the table. Once cooled and solidified, the plastic takes the shape of the mold, resulting in precise and consistent parts. Here are some key reasons why Jobr Tech's plastic injection molding is widely adopted:

Design Flexibility

Plastic injection molding offers unparalleled design freedom, allowing for complex geometries, intricate details, and various part sizes. This flexibility enables designers to bring their creative visions to life without compromising on functionality or aesthetics. Jobr Tech's experienced team produces high-quality injection molded products.

Cost-Effective Production

With the ability to produce large quantities of parts in a single production run, plastic injection molding offers significant cost advantages over other manufacturing methods. The high production efficiency and minimal material waste make it an economical choice for mass production. Jobr Tech uses custom plastic injection molding and rapid tooling capabilities, which allows it to create detailed custom parts quickly and efficiently.

Superior Quality and Consistency

Plastic injection molding ensures exceptional part quality and consistency. The process allows for tight tolerances, smooth finishes, and excellent surface details, meeting the highest standards of precision and aesthetics. Jobr Tech's plastic injection molding technology is capable of using a wide range of materials and finishes to meet the needs of any industry or application.

Material Versatility

Plastic injection molding supports a wide range of thermoplastic materials, including ABS, polypropylene, polycarbonate, and more. This versatility enables manufacturers to select the most suitable material properties for their specific application requirements.

Conclusion

Plastic injection molding has revolutionized the manufacturing industry, offering unparalleled design flexibility, cost-effective production, and superior part quality. By partnering with Jobr Tech, businesses can harness the power of plastic injection molding to drive innovation, enhance productivity, and gain a competitive edge in their respective markets.