Accelerate Your Product Development with JOBR Tech's Injection Molding Prototyping Service

- Release Time:29 / 11 / 2023

- Author: JOBR

In today's fast-paced business environment, companies need efficient solutions to accelerate their product development cycles. JOBR Tech, a leading plastic injection molding company, offers an exceptional injection molding prototyping service that can revolutionize your product development journey. With advanced techniques and a dedicated team of experts, we deliver high-quality prototypes quickly and cost-effectively. Read on to discover the applications, advantages, and the branded word "JOBR Tech" in injection molding prototyping.

Understanding Injection Molding Prototyping:

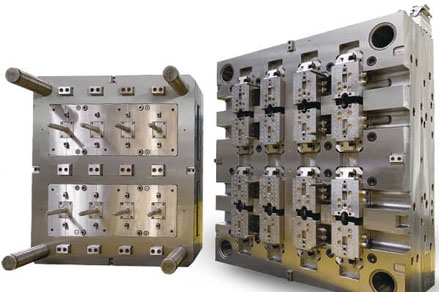

Injection molding prototyping is the process of creating functional prototypes using injection molding techniques. It enables businesses to produce small quantities of custom parts for testing, validation, and design optimization before proceeding to full-scale production. JOBR Tech leverages its expertise in injection molding to provide efficient and accurate prototyping solutions for a wide range of industries and applications.

Applications of Injection Molding Prototypes

Injection molding prototypes find applications across various industries:

Product Design and Development: Injection molding prototypes allow businesses to evaluate and refine their product designs before committing to mass production. JOBR Tech's injection molding prototyping service enables you to test the functionality, fit, and aesthetics of your designs, ensuring optimal performance and customer satisfaction.

Functional Testing: Injection molding prototypes are invaluable for conducting rigorous functional testing. By producing functional prototypes, we help businesses identify design flaws, assess product performance, and make necessary improvements early in the development process, saving time and costs.

Market Testing and Feedback: Injection molding prototypes can be used for market testing and gathering feedback from potential customers. JOBR Tech's prototyping service enables you to assess customer preferences, validate product features, and make informed decisions based on real-world feedback, helping you tailor your product to market demands.

Advantages of JOBR Tech's Injection Molding Prototyping Service

Partnering with JOBR Tech for your injection molding prototyping needs offers several advantages:

Rapid Turnaround Times: Our expertise in injection molding and rapid tooling capabilities allows for fast production of high-quality prototypes. Our efficient processes and advanced equipment ensure quick turnaround times, helping you accelerate your product development cycle.

Cost-Effective Solutions: Our injection molding prototyping service provides a cost-effective approach to product development. By producing accurate prototypes early in the design phase, you can identify and address any issues promptly, reducing the risk of costly errors during mass production.

Design Flexibility: We offer custom injection molding services and design freedom, allowing you to create complex geometries and intricate details. JOBR Tech's team of experts ensures that your design specifications are faithfully replicated in the prototypes, enabling you to visualize and refine your product with accuracy.

One-Stop Solution: We offer a comprehensive one-stop solution for injection molding and prototyping needs. From concept design to production, assembly, and packaging, JOBR Tech's seamless process ensures a hassle-free experience and saves you time and effort.

Conclusion

With the advantages of rapid turnaround times, cost-effectiveness, design flexibility, and comprehensive one-stop solutions, JOBR Tech stands out as a trusted partner for injection molding prototyping needs. By leveraging our expertise and cutting-edge technology, you can refine your designs, test functional performance, and gather valuable market feedback, ensuring the success of your products in today's competitive landscape. Contact JOBR Tech today to experience the benefits of our injection molding prototyping service and take your product development journey to new heights.